Gatorshield®

Gatorshield® manufactured by Allied Tube & Conduit is a patented triple layer Flo-Coat® rust and corrosion resistant product which has shown itself to be the best over the long haul versus all competitive product offerings. When rust and corrosion protection is needed …….. Gatorshield® is the best!

Additionally, the zinc rich interior coating provides the inside of the tube maximum corrosion and rust protection. Inside and out …….Gatorshield® is the best!

- It is available in round, square, and rectangular shapes ……. in a 1/2″ to 5″ O.D. size range …. in a .028 to .250 wall thickness (gauge) range.

- It delivers all end-users a smooth, shiny appearance.

- It can be easily fabricated ….. with no deformation or flaking of the base material.

- It can be produced in whatever length is meet your specific requirements.

Flo-Coat®

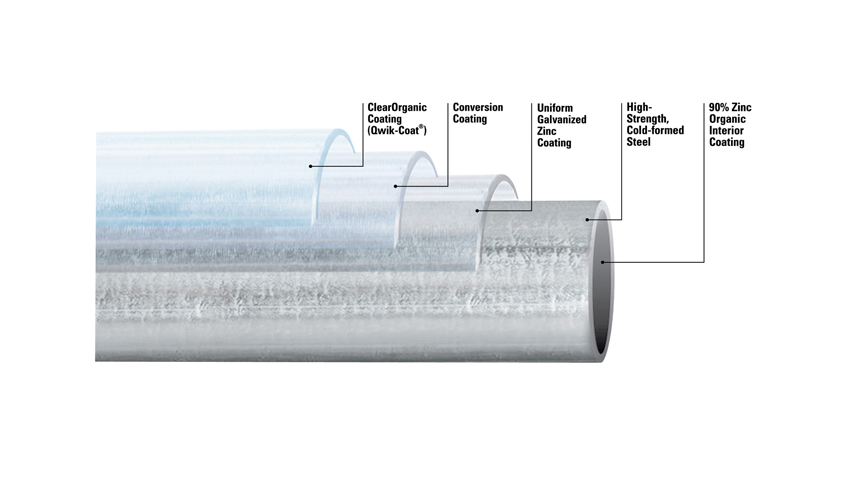

Flo-Coat process is the superior method of galvanizing steel tubing. It begins with flat strip steel, which is then cold-formed and electric-resistance or induction welded. After welding, the tube receives a triple layer of protection-zinc, conversion coating, and a clear polymer top-coat – all applied in-line to assure a uniform coating. The result is a smooth, shiny end product appearance that is unmatched in terms of strength and durability.

Flo-Coat tubing exhibits greater corrosion resistance because of the synergism created between the coatings; the conversion coating passivates the zinc to slow down the white rust growth process, and the clear top-coat then “seals in” the protection.

The triple coat corrosion provided by Allied’s in-line manufacturing processes has never been equaled. This triple layer protection (zinc, conversion coating and clear organic polymer) provides a smooth, shiny product appearance that is unmatched in terms of strength and durability.

Details of the Flo-Coat Process

The Allied Flo-Coat Process Inherent Advantages…

- The cold-forming and quenching process creates greater yield and tensile strength than competitive product alternatives.

- The tube is welded prior to the application of coating; thus, the weld area is as protected from corrosion as the rest of the tube body.

- Flo-Coat tubing exhibits greater corrosion resistance because of the synergism created between the coatings; the conversion coating passivates the zinc to slow down the white rust growth process, and the clear top-coat then “seals in” the protection.

- The clear third coating also acts as a primer for painting or powder coating. Extensive pre-cleaning is unnecessary, and excellent adhesion is achieved, even at high baking temperatures.

- Powder coating over Allied’s galvanized substrate provides substantial corrosion resistance superiority over powder coating a raw/uncoated substrate. Powder coating over a galvanized surface provides corrosion protection 5-6 times longer than the same over raw or bare surface.

- Welding Flo-Coat is easily done in the exact same manner as welding bare steel. Allied´s zinc coating contains the lowest lead content achievable (99.9% pure zinc, average 13 ppm), so lead oxide fumes generated during welding are kept to an absolute minimum. Hot-dip galvanized products usually contain up to .5% lead (5000 ppm).

- Allied’s galvanized products can be easily fabricated…bent, swaged, wall-to-wall flattened…without deformation of the triple layer of protection. Competitive products tend to flake and chip during fabrication.

Have a question about Gatorshield® or Flo-Coat®?

Weight Per Foot Charts

| ROUNDS | ||||||||||||||||

| OD | Equiv. Sizes (In) | 22 | 20 | 19 | 18 | 17 | 16 | 15 | 14 | 13 | 12 | 11 | 10 | 9 | 8 | 7 |

| 0.028 | 0.035 | 0.042 | 0.049 | 0.058 | 0.065 | 0.072 | 0.083 | 0.095 | 0.109 | 0.12 | 0.134 | 0.148 | 0.165 | 0.18 | ||

| 0.5 | 0.1413 | 0.174 | 0.2056 | 0.2362 | 0.274 | 0.3023 | ||||||||||

| 0.625 | 0.1787 | 0.2207 | 0.2618 | 0.3017 | 0.3516 | 0.3891 | ||||||||||

| 0.706 | 1⁄2 EMT | 0.2029 | 0.2511 | 0.2981 | 0.3441 | 0.4018 | 0.4454 | |||||||||

| 0.75 | 0.2161 | 0.2675 | 0.3179 | 0.3672 | 0.4291 | 0.476 | 0.5218 | |||||||||

| 0.815 | 1⁄2 IMC | 0.2356 | 0.2918 | 0.3471 | 0.4012 | 0.4694 | 0.5211 | 0.5719 | 0.6495 | |||||||

| 0.87 | 0.252 | 0.3124 | 0.3718 | 0.43 | 0.5035 | 0.5594 | 0.6142 | |||||||||

| 0.875 | 0.2535 | 0.3143 | 0.374 | 0.4327 | 0.5066 | 0.5628 | 0.6181 | |||||||||

| 0.922 | 3⁄4 EMT | 0.2676 | 0.3319 | 0.3951 | 0.4573 | 0.5357 | 0.5955 | 0.6542 | 0.7444 | |||||||

| 0.98 | 0.285 | 0.3535 | 0.4211 | 0.4877 | 0.5717 | 0.6358 | 0.6989 | 0.7959 | ||||||||

| 0.995 | 0.2894 | 0.3592 | 0.4279 | 0.4955 | 0.581 | 0.6462 | 0.7104 | 0.8092 | ||||||||

| 1 | 0.2909 | 0.3611 | 0.4301 | 0.4981 | 0.5841 | 0.6497 | 0.7143 | 0.8136 | ||||||||

| 1.029 | 0.2996 | 0.3719 | 0.4431 | 0.5133 | 0.602 | 0.6698 | 0.7366 | 0.8394 | ||||||||

| 1.125 | 0.3284 | 0.4078 | 0.4862 | 0.5636 | 0.6616 | 0.7365 | 0.8105 | 0.9245 | ||||||||

| 1.163 | 1 EMT | 0.422 | 0.5033 | 0.5835 | 0.6851 | 0.7629 | 0.8397 | 0.9583 | ||||||||

| 1.187 | 0.5141 | 0.5961 | 0.7 | 0.7796 | ||||||||||||

| 1.25 | 0.4546 | 0.5424 | 0.6291 | 0.7391 | 0.8234 | 0.9067 | 1.0354 | 1.173 | 1.3295 | 1.4496 | 1.5986 | |||||

| 1.29 | 1 IMC | 0.5603 | 0.65 | 0.7639 | 0.8512 | 0.9375 | 1.0709 | 1.2136 | 1.3761 | 1.5009 | 1.6559 | |||||

| 1.315 | 1 NPS | 0.4789 | 0.5716 | 0.6631 | 0.7794 | 0.8686 | 0.9567 | 1.0931 | 1.239 | 1.4052 | 1.5329 | 1.6917 | ||||

| 1.375 | 0.5014 | 0.5985 | 0.6946 | 0.8166 | 0.9103 | 1.0029 | 1.1464 | |||||||||

| 1.5 | 0.5481 | 0.6546 | 0.76 | 0.8941 | 0.9971 | 1.0991 | 1.2573 | 1.4268 | 1.6208 | 1.7703 | 1.9567 | |||||

| 1.51 | 1 1⁄4 EMT | 0.5519 | 0.6591 | 0.7653 | 0.9003 | 1.0041 | 1.1068 | 1.2661 | 1.437 | 1.6325 | 1.7831 | 1.9711 | ||||

| 1.625 | 0.8255 | 0.9716 | 1.084 | 1.1953 | 1.3682 | 1.5538 | 1.7665 | 1.9306 | 2.1358 | |||||||

| 1.638 | 1 1⁄4 IMC | 0.7166 | 0.8323 | 0.9796 | 1.093 | 1.2053 | 1.3797 | 1.567 | 1.7816 | 1.9473 | 2.1544 | |||||

| 1.66 | 1 1⁄4 NPS | 0.4885 | 0.608 | 0.7264 | 0.8439 | 0.9933 | 1.1083 | 1.2223 | 1.3992 | 1.5893 | 1.8072 | 1.9755 | 2.1859 | |||

| 1.69 | 1.1291 | 1.2453 | 1.4258 | 1.6198 | 1.8422 | 2.014 | 2.2289 | |||||||||

| 1.74 | 1 1⁄2 EMT | 0.6379 | 0.7624 | 0.8858 | 1.0429 | 1.1639 | 1.2838 | 1.4702 | ||||||||

| 1.75 | 0.6417 | 0.7669 | 0.891 | 1.0491 | 1.1708 | 1.2915 | 1.4791 | |||||||||

| 1.764 | 0.6469 | 0.7731 | 0.8983 | 1.0578 | 1.1806 | 1.3023 | 1.4915 | |||||||||

| 1.875 | 0.823 | 0.9565 | 1.1266 | 1.2577 | 1.3877 | 1.59 | ||||||||||

| 1.883 | 1 1⁄2 IMC | 0.8266 | 0.9607 | 1.1315 | 1.2632 | 1.3939 | 1.5971 | 1.8158 | 2.0671 | 2.2616 | 2.5054 | |||||

| 1.9 | 1 1⁄2 NPS | 0.6978 | 0.8342 | 0.9696 | 1.1421 | 1.275 | 1.407 | 1.6122 | 1.8331 | 2.0869 | 2.2834 | 2.5297 | 2.7719 | |||

| 1.948 | 0.7157 | 0.8558 | 0.9947 | 1.1718 | 1.3084 | 1.4439 | 1.6548 | |||||||||

| 1.968 | 50 MM | 0.7232 | 0.8647 | 1.0052 | 1.1842 | 1.3223 | 1.4593 | 1.6725 | ||||||||

| 2 | 0.7352 | 0.8791 | 1.022 | 1.2041 | 1.3445 | 1.4839 | 1.7009 | 1.9346 | 2.2034 | 2.4117 | 2.673 | 2.9301 | ||||

| 2.197 | 2 EMT | 1.4814 | 1.6356 | 1.8757 | 2.1347 | 2.433 | 2.6644 | 2.9552 | 3.2418 | |||||||

| 2.36 | 2 IMC | 1.2105 | 1.4273 | 1.5947 | 1.761 | 2.0203 | 2.3002 | 2.6229 | 2.8735 | 3.1887 | 3.4996 | |||||

| 2.375 | 2 NPS | 1.0475 | 1.2184 | 1.4366 | 1.6051 | 1.7726 | 2.0336 | 2.3155 | 2.6404 | 2.8927 | 3.2101 | 3.5234 | 3.8981 | 4.2236 | ||

| 2.5 | 1.692 | 1.8688 | 2.1445 | 2.4424 | 2.786 | 3.0531 | 3.3892 | 3.7211 | 4.1186 | 4.461 | ||||||

| 2.857 | 2 1⁄2 IMC | 2.1436 | 2.4613 | 2.8049 | 3.202 | 3.511 | 3.9006 | 4.286 | 4.7483 | 5.1511 | ||||||

| 2.875 | 2 1⁄2 NPS | 2.1574 | 2.4773 | 2.8232 | 3.223 | 3.5341 | 3.9264 | 4.3144 | 4.78 | 5.1857 | ||||||

| 3 | 2.2536 | 2.5882 | 2.9502 | 3.3686 | 3.6945 | 4.1054 | 4.5122 | 5.0005 | 5.4262 | |||||||

| 3.476 | 3 IMC | 2.62 | 3.0105 | 3.4336 | 3.9233 | 4.3051 | 4.7873 | 5.2653 | 5.8401 | 6.3422 | ||||||

| 3.5 | 3 NPS | 2.6385 | 3.0318 | 3.4579 | 3.9512 | 4.3359 | 4.8217 | 5.3033 | 5.8824 | 6.3883 | ||||||

| 3.971 | 3 1⁄2 IMC | 3.4497 | 3.9363 | 4.5 | 4.9401 | 5.4963 | 6.0484 | 6.7132 | 7.2946 | |||||||

| 4 | 3 1⁄2 NPS | 3.4754 | 3.9657 | 4.5338 | 4.9773 | 5.5379 | 6.0943 | 6.7644 | 7.3504 | |||||||

| 4.466 | 4 IMC | 3.382 | 3.8889 | 4.439 | 5.0768 | 5.575 | 6.2054 | 6.8316 | 7.5863 | 8.2471 | ||||||

| 4.5 | 4 NPS | 3.4081 | 3.9191 | 4.4735 | 5.1164 | 5.6187 | 6.2541 | 6.8854 | 7.6463 | 8.3125 | ||||||

| 5 | 4 1⁄2 NPS | 4.9813 | 5.699 | 6.2601 | 6.9704 | 7.6764 | 8.5282 | 9.2746 |

| SHAPES | |||||||||||||||||

| Size | RTS | WIC | 20 | 19 | 18 | 17 | 16 | 15 | 14 | 13 | 12 | 11 | 10 | 9 | 8 | 7 | |

| 0.035 | 0.042 | 0.049 | 0.058 | 0.065 | 0.072 | 0.083 | 0.095 | 0.109 | 0.12 | 0.134 | 0.148 | 0.165 | 0.18 | ||||

| SQUARE | 0.625 | X | 0.281 | 0.3333 | 0.3841 | 0.4476 | 0.4954 | ||||||||||

| 0.709 | X | 0.3211 | 0.3813 | 0.4401 | |||||||||||||

| 0.75 | X | 0.3406 | 0.4047 | 0.4675 | 0.5463 | 0.606 | 0.6644 | 0.7535 | |||||||||

| 0.813 | X | 0.3706 | 0.4407 | 0.5095 | 0.596 | 0.6617 | 0.7261 | 0.8246 | |||||||||

| 0.875 | X | 0.4001 | 0.4762 | 0.5509 | 0.6449 | 0.7166 | 0.7869 | 0.8947 | |||||||||

| 0.975 | X | 0.6175 | 0.7239 | 0.805 | 0.8849 | 1.0076 | |||||||||||

| 1 | X | 0.4597 | 0.5476 | 0.6342 | 0.7436 | 0.8271 | 0.9094 | 1.0359 | 1.1701 | 1.3218 | |||||||

| 1.250* | X | X | 0.5788 | 0.6905 | 0.8009 | 0.9409 | 1.0483 | 1.1543 | 1.3183 | 1.4934 | 1.6927 | 1.8455 | |||||

| 1.500* | X | X | 0.6979 | 0.8334 | 0.9677 | 1.1383 | 1.2695 | 1.3993 | 1.6007 | 1.8166 | 2.0635 | 2.2538 | |||||

| 1.625 | X | 1.3801 | 1.5218 | 1.7419 | 1.9782 | 2.249 | 2.458 | ||||||||||

| 1.750* | X | 1.4906 | 1.6443 | 1.8831 | 2.1398 | 2.4344 | 2.6621 | ||||||||||

| 1.875 | X | 2.6198 | |||||||||||||||

| 2.000* | X | X | 1.7118 | 1.8893 | 2.1655 | 2.4631 | 2.8053 | 3.0704 | 3.4031 | 3.7304 | 4.1208 | 4.4586 | |||||

| 2.188 | X | 3.746 | |||||||||||||||

| 2.250* | X | X | 2.1343 | 2.4479 | 2.7863 | 3.1762 | 3.4787 | 3.859 | |||||||||

| 2.500* | X | X | 2.3792 | 2.7303 | 3.1095 | 3.547 | 3.887 | 4.315 | 4.7376 | 5.2436 | |||||||

| 3 | X | 2.5964 | 2.8692 | 3.2951 | 3.756 | 4.2888 | 4.7036 | 5.2268 | 5.7447 | 6.3664 | 6.9084 | ||||||

| 4 | X | 4.4248 | 5.049 | 5.7723 | 6.3368 | 7.0506 | 7.759 | 8.6121 | 9.3582 | ||||||||

| FLAT SIDED OVAL | .750x1.000 | 0.3319 | 0.3951 | 0.4573 | 0.5357 | 0.5955 | |||||||||||

| 1.500x1.000 | 0.4789 | 0.5716 | 0.6631 | 0.7794 | 0.8686 | ||||||||||||

| 1.75x1.125 | 0.5519 | 0.6591 | 0.7653 | 0.9003 | 1.0041 | 1.1068 | 1.2661 | ||||||||||

| 2.000x1.094 | 0.608 | 0.7264 | 0.8439 | 0.9933 | 1.1083 | ||||||||||||

| 2.250x1.313 | 0.6978 | 0.8342 | 0.9696 | 1.1421 | 1.275 | ||||||||||||

| 2.375x1.625 | 1.1251 | 1.3262 | 1.4814 | ||||||||||||||

| RECTANGLE | .625x1.125 | 0.4001 | 0.4762 | 0.5509 | 0.6449 | 0.7166 | |||||||||||

| .750x1.500 | 0.5192 | 0.6191 | 0.7176 | 0.8423 | 0.9377 | 1.0319 | 1.1771 | ||||||||||

| .750x2.250 | 0.6979 | ||||||||||||||||

| .875x1.917 | 0.6483 | 0.774 | 0.8983 | 1.0562 | 1.1775 | ||||||||||||

| 1.000x1.750 | 0.6383 | 0.762 | 0.8843 | 1.0396 | 1.1589 | ||||||||||||

| 1.000x2.000 | 0.6979 | 0.8334 | 0.9677 | 1.1383 | 1.2695 | 1.3993 | 1.6007 | ||||||||||

| 1.500x2.000 | 0.8169 | 0.9763 | 1.1344 | 1.3356 | 1.4906 | 1.6443 | 1.8831 | 2.1398 | 2.4344 | 2.6621 | |||||||

| 1.500x2.500 | 1.1192 | 1.3011 | 1.533 | 1.7118 | 1.8893 | 2.1655 | 2.4631 | 2.8053 | 3.0704 | 3.4031 | |||||||

| 1.500x3.000 | 2.7863 | 3.1762 | 3.4787 | ||||||||||||||

| 1.500x3.500 | 1.6345 | 1.9277 | 2.1541 | 2.3792 | 2.7303 | 3.1095 | 3.547 | 3.887 | 4.315 | ||||||||

| 1.540x3.110 | 3.2874 | ||||||||||||||||

| 1.625x3.000 | 2.5185 | 2.8671 | 3.2689 | 3.5808 | |||||||||||||

| 2.000x3.000 | 2.1541 | 2.3792 | 2.7303 | 3.1095 | 3.547 | 3.887 | 4.315 | 4.7376 | 5.2436 | 5.6835 | |||||||

| 2.000x4.000 | 3.2951 | 3.756 | 4.2888 | 4.7036 | 5.2268 | 5.7447 | 6.3664 | ||||||||||

| 2.000x5.000 | 3.8599 | 4.4025 | 5.0305 | 5.5202 | 6.1387 | 6.7519 | 7.4892 | ||||||||||

| 2.360x4.720 | 4.4542 | 5.0899 | 5.5855 | 6.2117 | 6.8324 | ||||||||||||

| 3.000x4.000 | 4.4025 | 5.0305 | 5.5202 | 6.1387 | 6.7519 | 7.4892 | 8.1333 | ||||||||||

| OCTAGON | 4.783 | 5.7505 | 6.3159 | 7.0316 | 7.7429 | 8.6006 |